Top 5 Effective Ways to Build a Workbench in 2025

Building a sturdy and functional workbench is essential for any woodworking enthusiast and DIYer. Whether you’re embarking on a woodworking project or just need a reliable workspace, knowing how to build a workbench tailored to your needs will enhance your productivity. In this article, we will explore five effective ways to construct a workbench in 2025, featuring practical tips to help you create the perfect workspace.

1. Planning Your Workbench Design

Before you begin construction, effective planning is vital for your workbench design. Consider the type of projects you’ll undertake and how much space you have available. Evaluate whether you need a compact option for limited room or a more spacious model for larger tasks. Take measurements to ensure your workbench will fit comfortably in your workshop. Also, make a list of the workbench tools and accessories you frequently use to ensure everything is easily accessible.

Selecting Materials for a Workbench

The materials you choose for your workbench will determine its durability and functionality. A popular choice is solid wood, which provides stability and a robust working surface. However, also consider using plywood, particleboard, or even reclaimed wood for a homemade workbench that’s environmentally friendly. Each material has unique advantages, so choose one that aligns with your workbench woodworking techniques and desired aesthetic.

Installing Height Adjustable Features

One effective strategy is to incorporate a height adjustable workbench. This feature ensures that anyone using the workbench can optimize their ergonomic setup, reducing strain during prolonged work. You can achieve this by using adjustable legs or a built-in mechanism that allows easy height changes. This way, your workbench adapts to various tasks, enhancing overall efficiency.

2. Workbench Assembly Techniques

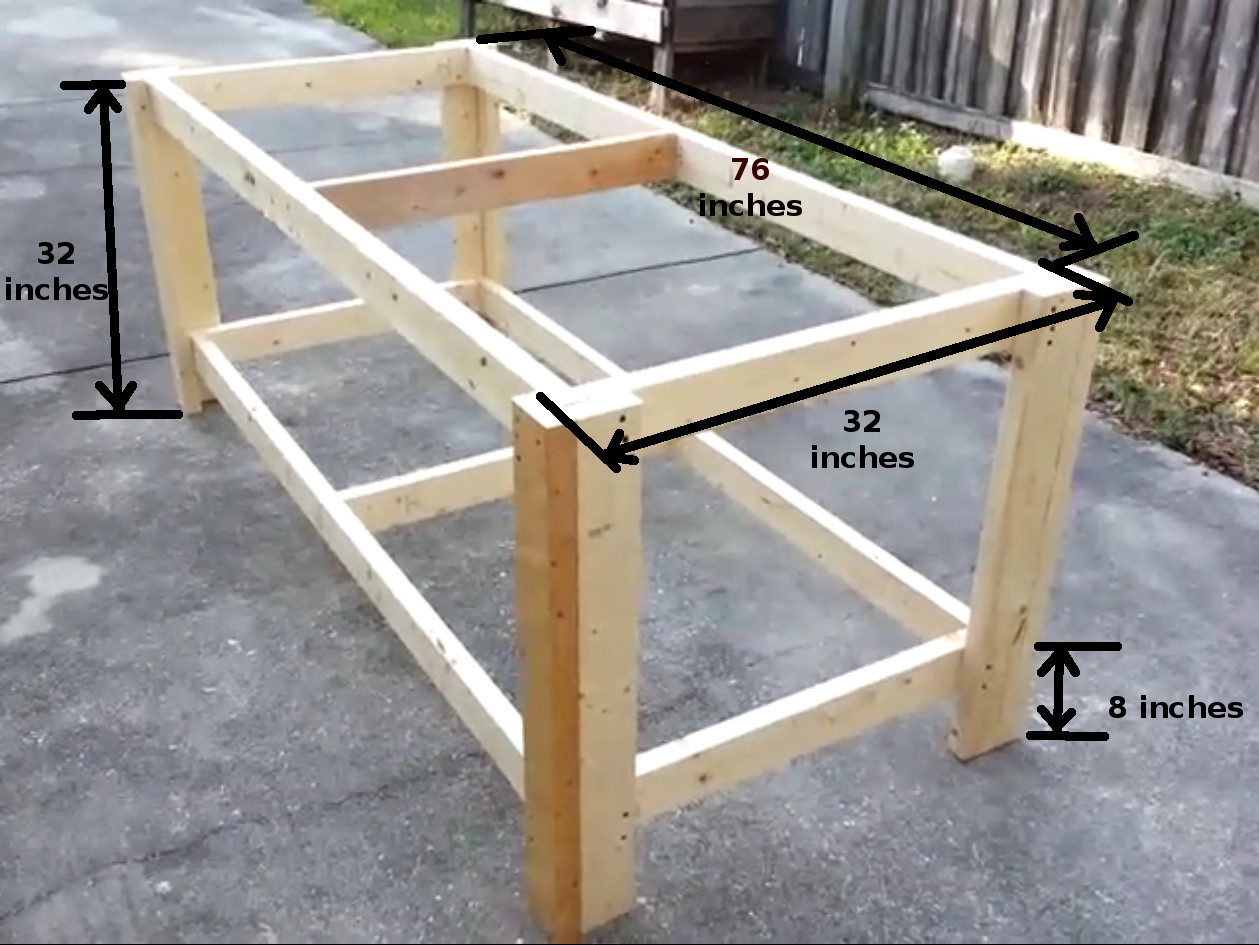

Once you’ve settled on a design, it’s time for workbench assembly. Solid assembly methods are essential for a reliable structure. For starters, utilize a strong adhesive combined with screws to secure joints, providing strength while minimizing wobble. Pay attention to the details of your workbench measurements, especially in framing the legs and adding sufficient bracing to support any heavy loads.

User-Friendly Workbench Layouts

Incorporating a thoughtful layout can significantly optimize your workspace. Customize your workbench to include drawers or shelves for easy workbench storage. Implementing workbench organization strategies means your tools are always at hand, aiding your workflow. Ensure that your bench is equipped with a grid design or a tool board in the background for quick accessibility.

Stability Considerations

Creating a stable foundation is crucial for any workbench. Adding cross braces between the legs and choosing a wide stance can help mitigate vibrations and enhance support. This is particularly important for those considering heavy-duty usage or woodworking projects that require precision. You may also inspect your workbench stability tips to prevent wobbles that can hinder your projects.

3. Exploring Modern Workbench Designs

As we embrace new innovations, designs for workbenches continue to evolve. Modern workbench styles can fit seamlessly into contemporary workshops, often enhancing not only functionality but also aesthetics. You may explore projects for workbench that utilize minimalist styles with clean lines to harmonize with current interiors while maintaining utility.

Custom Workbench Options

Searching for something unique? Consider investing time in a custom workbench. Tailored designs can be created based on your specific needs, allowing for unique features or dimensions. This approach lets you incorporate built-in features such as tool chests or an easily accessible project area. If you’re an advanced user, you might even explore workbench plans that appeal to your woodworking skills.

Utilizing Space-Saving Solutions

If space is a premium concern, you might be interested in a space-saving workbench. A folding workbench design enables you to set up a workspace as needed while providing you with flexibility when it’s not in use. Look into building a mobile workbench on wheels to enhance your store’s versatility, allowing you to move the work area to where it’s most effective.

4. Finishing Touches for Your Workbench

Your workbench is just about complete, and it’s time to make those finishing touches! The finish you apply can significantly impact your workbench’s longevity and appearance. Use stains and sealants to protect your surface from wear and tear, providing a finish that complements your workspace.

Workbench Finishes and Care

Applying a polyurethane finish can add an extra layer of protection and durability to your workbench. Be mindful when choosing products that are easy to clean and won’t compromise your working surface. Regular maintenance, such as reapplying finishes or cleaning your workbench surface after heavy use, will ensure it stays in optimal condition for years to come.

Improving Your Workbench Skills

Finally, as you grow in your woodworking abilities, continually seek to improve your workbench skills. Engage in woodworking basics workshops or online tutorials focused on advanced techniques and tools. The more adept you become at utilizing your workbench, the more efficiently and creatively you can explore your projects.

Key Takeaways

- Effective planning is crucial to selecting the right workbench design and materials.

- Assembly techniques significantly affect your workbench’s stability and performance.

- Modern designs and customization options can enhance your workspace.

- Finishing touches not only protect but also beautify your workbench.

- Continually improving your skills ensures a productive and enjoyable woodworking experience.

FAQ

1. What are the best materials for building a DIY workbench?

Wood is often the best material for a DIY workbench, but options like plywood or sturdy plastic may also be viable based on your needs. A solid wood workbench provides stability, while plywood may reduce costs and weight.

2. How important is workbench height?

Workbench height plays a significant role in ergonomics and overall comfort. Ideally, the working surface should be at elbow height to avoid undue strain during use and improve project accuracy.

3. Can I build a portable workbench myself?

Absolutely! Many plans are available for building a portable workbench that includes foldability or wheels. This adaptability makes it ideal for small spaces or mobile woodworkers.

4. What features should I consider when designing a workshop workbench?

Consider storage options, adjustable height, bench dimensions, and any specialized features (like drawers or toolholders) that enhance your efficiency and ease of use.

5. How can I stabilize my workbench?

Stability can be improved by ensuring a solid frame, adding weight to the base, and using anti-vibration techniques such as rubber pads or a well-thought-out leg design for your bench.

For more detailed insights on building a workbench, check out the links: Bench Plans and Workbench Tools Guide.